- Home

- Panino

- Engineering

- ventilated facades

- SYSTEMS WITH HIDDEN ANCHORING

Systems with hidden anchoring

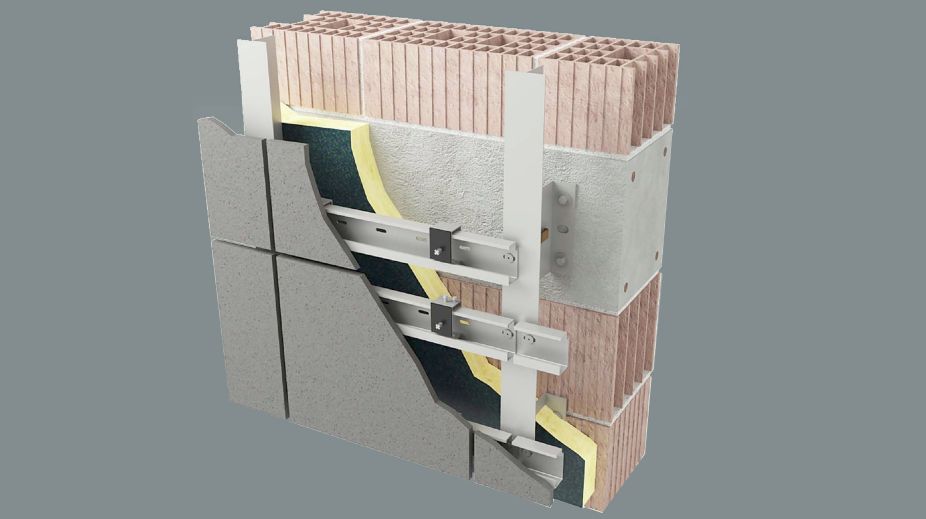

All these systems essentially consist of: suitable anchors based on the existing masonry, brackets, uprights and in some cases horizontal currents or tracks applied directly to the tile. In addition to mechanical anchoring, this type of facade includes glued or hybrid systems which, thanks to continuous research in the field, have managed to reach and in some cases exceed, the same quality and resistance standards as mechanical systems. All the systems proposed by Italgraniti are resistant to atmospheric agents and once installed have practically no maintenance and guarantee the inspection of the entire system.

Invisible system with open joint KEIL coupling

This system foresees a predisposition of the facing slabs, which consists of a mechanical processing to be carried out on the back of the slab and the subsequent insertion of special steel inserts.

This arrangement is specifically designed for the anchoring of staples which will then be hooked to the horizontal profile.

System components

- Uprights with "T" section

- "L" -shaped anchoring brackets complete with spring for prefixing

- Anchor plugs suitable for the support

- Normalized rivets for fixing the uprights to the brackets

- Slotted horizontal beams, with a particular section, designed to receive the staples applied on the back of the facing with an anti-tipping joint,

- Normalized rivets for fastening the battens to the uprights

- Anchoring clips with millimeter adjustment, equipped with tightening and adjusting screw

- Simple anchoring clips

- Neoprene gaskets to be applied between the anchoring clip and the cladding plate

INVISIBLE SYSTEM WITH CLOSED JOINT

The ventilated facade will consist of a substructure made of EN AW-6060 aluminum profiles, machined and pre-assembled to the slab according to the orthogonal lines of the project and adapted to the dimensions of the finishing slabs.

The pre-assembly must take place using inserts with bayonet joint after suitable blind drilling on the back of the finishing plate; the inserts will be tightened by means of stainless steel screws and the profiles (equipped with a special housing) will have to collaborate with the finishing plates using suitable structural adhesives, in order to increase their strength and make the plates safe.

The system

The substructure will be equipped with joints with tolerances of ± 2/10 mm, having the function of constraining the alignment of the slabs and ensuring a constant and predetermined size of the joints, also allowing the reduction to the register during the work.

The substructure profiles will be equipped with special guides to house the anchoring system (bracket and hook) point to the wall (bricks, reinforced concrete or load-bearing structural elements), the bracket and the hook will allow the safe and punctual fixing of each single slab. (230 kg with normal traction to the facade plane which corresponds to the resistance along the stress vectors due to the wind).

Invisible system with patented undercut coupling

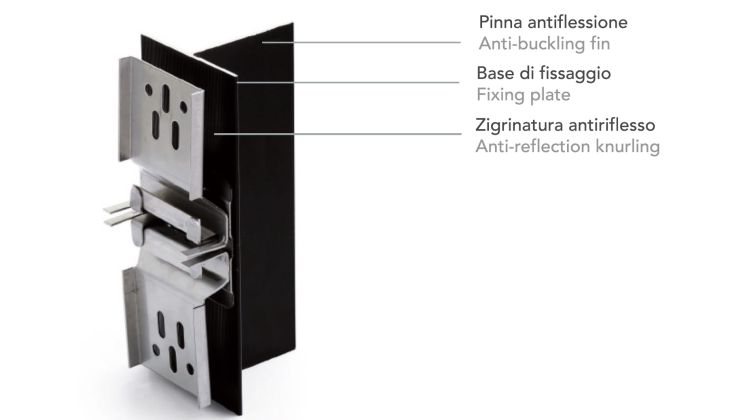

System with patented concealed hooking of the cladding having as a structural base an extruded aluminum alloy 6060T5 profile, positioned along the vertical joint lines, according to the finishing step. The uprights that make up the structure are made with various tubular geometries with a knurled outer side, suitable for accommodating both the accessories for supporting the cladding plates and the necessary rear brackets.

The brackets are anchored to the wall support by means of suitable plugs and equipped with slots that allow perfect registration of the flatness of the facade.

The system

The undercut mechanical anchoring elements applied on the back of the slabs, international patent PCT-WO-02/053859, are made entirely of AISI 304 stainless steel, are quick and easy to assemble and extremely tough.

The assembly of the slabs is completed by locking the slats to stainless steel plates equipped with bolts and shaped in such a way that they can subsequently be coupled to the supporting frame. This anchoring system has obtained the E.R.I.C.A.certification, for its resistance to freeze-thaw cycles, and provides for a particular patented connection system (patent RE2008A000080) which allows the cladding slabs to be tied directly to the main uprights.

All the load-bearing components of the structure comply with the UNI 11018 standard.

© 2022 ITALGRANITI GROUP S.P.A.

Via Radici in Piano, 355

41043 Formigine - Modena - Italy

C.F. / P.IVA 03294200369

Tel: +39 059 888411 - Fax: +39 059 848808

This email address is being protected from spambots. You need JavaScript enabled to view it.